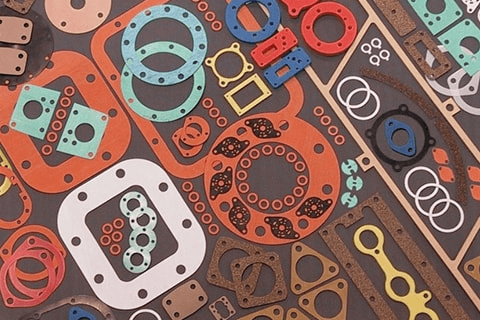

Gaskets do more than fill space between two surfaces—they keep systems sealed, safe, and functional. Whether you’re working with a vacuum tank, a pressure vessel, or a processing line, the gasket plays a quiet but essential role in keeping everything tight and leak-free. And like most unsung heroes in industrial systems, there’s more going on beneath the surface.

A gasket is a compressible sealing material placed between two flanges or surfaces. Its job is to create a seal that compensates for surface imperfections and holds up under pressure, temperature shifts, vibration, and chemical exposure. Sounds simple, but choosing the wrong gasket can lead to leaks, equipment failure, or contamination—so understanding your options matters.

Common Gasket Materials

Not all gaskets are the same, and the material makes all the difference.

- Rubber (Nitrile, EPDM, Neoprene): Flexible, durable, and used in water systems and general industrial sealing. Each type has strengths—nitrile handles oils well, EPDM resists weather and steam.

- Viton®: A high-performance fluoroelastomer known for its resistance to chemicals and high temperatures. Common in fuel systems and chemical processing.

- PTFE (Teflon®): Non-reactive and incredibly resistant to corrosion. Often found in food, beverage, and pharmaceutical applications.

- Cork and Rubber Blends: Lightweight and compressible—good for low-pressure systems with oil or fuel.

- Compressed Non-Asbestos Fiber (CNAF): A workhorse material used in many flange gaskets for steam, oil, and chemicals.

- Metal (spiral wound, jacketed): Used in high-pressure or high-temperature environments like boilers, refineries, and power plants.

Specialty Gaskets

In more demanding settings, a basic gasket won’t cut it. Specialty gaskets are designed with specific functions or environments in mind. Some examples are the following:

- Manway gaskets: Designed for access points on vacuum tanks and vessels. These need precise sealing to prevent leaks under pressure or vacuum.

- Sanitary gaskets (Tri-Clamp®): Common in food and beverage industries. These gaskets prevent contamination and must meet strict FDA and 3A standards.

- High-temp gaskets: Made of graphite or metal blends to handle extreme heat without degrading.

- PTFE envelope gaskets: Combine the chemical resistance of PTFE with the compressibility of a filler material. Great for aggressive media and uneven surfaces.

Choosing the right gasket isn’t about grabbing something that fits—it’s about knowing what your system needs to stay sealed under real-world conditions. That knowledge can save time, product, and plenty of cleanup.

Leave a comment